Main Features

1.The process of pre-cooling and drying finishes in the chamber. The drying process is automatic;

2.The shelf uses circulating medium, the shelf temperature is adjustable and the difference is less than or equal to 1℃. The drying effect is uniform;

3.Touch screen operation, PLC controlling, and real-time monitoring;

4.Connecting to the computer, remote control, and freeze-drying curve recording;

5.The integrated design is easy to transport and install, and also save space;

6.The CIP and SIP cleaning system, hydraulic system and other system are optional.

Applicable Range

1.Pharmaceutical industry: vacuum freeze-drying can be applied in the drying of serum, plasma, vaccines, enzymes, hormones and so on.

2.Food industry: it can dry the coffee, vegetable, fruit, meet and maintain the original color, aroma, taste, appearance and nutrients of them, which will be easily preserved and transport.

3.Nutrition health industry: with the freeze-drying of royal jelly, ginseng, terrapin, pearl, snake, turtle, the nutrients and active component of these products won’t loss.

4.Biological study: the freeze-drying can long preserve blood, bacteria, artery, bones, skin, nerve tissue, organs, which can rebirth with water completely.

5.Others: it has a unique effect in producing adiabatic ceramic in space industry and storing specimens and relic in archaeological industry.

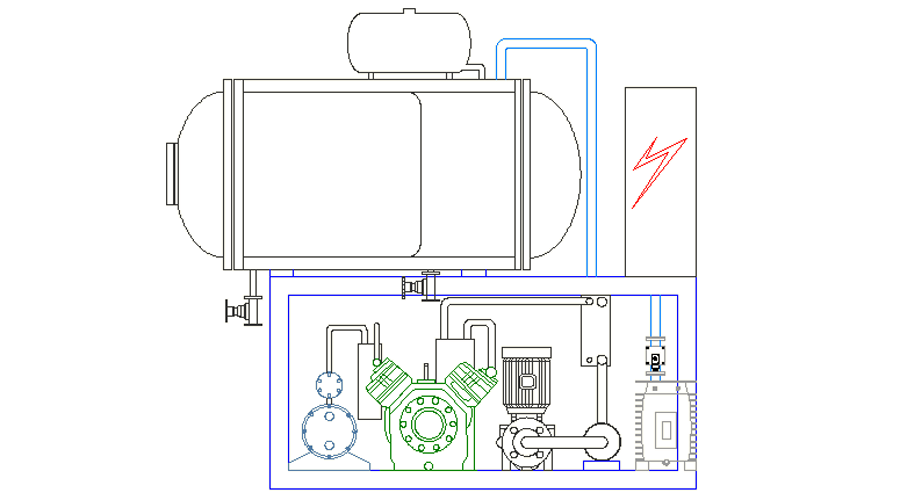

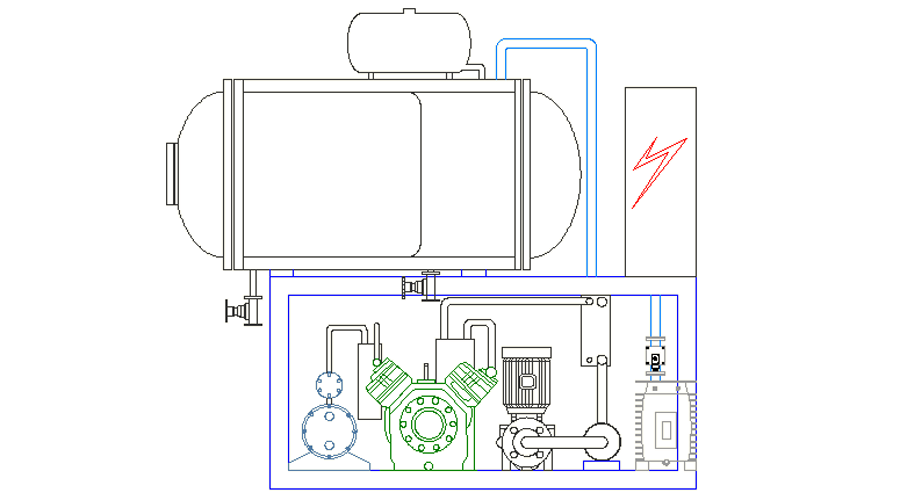

Plan Drawing (Reference)

The Principle of Freeze Drying

One way of keep food without spoilage is drying. There are many ways to dry, like sun drying, boil drying, spray drying and vacuum drying and etc. But these drying method is processing over 0

℃ or higher temperature. There are many disadvantages: the products are generally smaller in size, the hard texture, and some substances will even oxidize, most of the volatile components will lose, and some heat-sensitive material, such as protein, vitamins will change their nature, the microbes will loss the biological activity, and the dried material is not easily dissolved in water. Therefore, the dried products have a lot in nature compared with the fresh one. The freeze-drying method is different from the above, basically the drying temperature is below 0

℃, and in order to further reduce the residual moisture, it needs to rise the temperature above 0

℃, but generally won’t over 50

℃.

Freeze-drying is to pre-freeze the material into solid state that contains large amount of water, then sublimate the water vapor directly out of the material under vacuum condition, so it will keep its original size. The temperature’s drop of the product will slow down the speed of sublimation, in order to increase the sublimation rate to shorten the drying time, the product must be properly heated. The Freeze-drying process is carried out under lower temperature.

The advantages of Freeze Drying

1.Low temperature freeze-drying is practically suitable for heat-sensitive material. Such as protein, microorganisms, they won’t degeneration or lose biological activity with freeze-drying, so it is widely used in medical industry.

2.Dry at low temperature, the loss of some volatile components is very small. So it is fit for some chemical products, pharmaceuticals and food drying.

3.During the freeze-drying process, the growth of microorganisms and enzymes function does not proceed, so they can maintain the original character.

4.Freeze-drying within the frozen state, the volume is almost unchanged and maintain the original structure, and no enrichment phenomenon.

5.After drying, the material will be loose and porous, like sponge. After adding water the material dissolves rapidly and completely and regain the original character almost immediately.

6.As drying under vacuum, there is little oxygen, so a number of easily oxidized components have been protected.

7.Drying can eliminate more than 95-99% of moisture, so that the dried product can be stored for a long time without deterioration.

Therefore, the freeze-drying is widely used in pharmaceutical industry, food industry, researches and other ways.